The Chinese owners of Amca pulled out of Ten Post last year. At first glance, this was sad and unfortunate, as a fine company in hydraulics went to the grave. But former employees immediately saw an opportunity. One of them, Ken Dijk, now runs Wotan in Hoogezand. With former machines from Amca.

It is not surprising that Ken Dijk took that step. Metalworking is his passion and he is enterprising. A telling example from the past: he had just finished the MTS in Appingedam and saw that there was a job at Waukesha - the company that had taken over the legendary and publicly traded Brons Motoren. Instead of writing or calling, he walked straight to the factory and asked for someone from the HR department.

Right on target

Ken Dijk: "Oh, is that how you do it?" the guy from HR asked. I explained that I lived nearby and it seemed like the short cut. The manager was called in and he also said, "Oh, is that how you do it? Then he asked how you calculate the cutting speed. I knew that formula by heart and a little later we walked around the factory. We came to a Wotan brand CNC boring machine (on which tools rotate instead of the products). That's where it all started, it became my first job.'

So, that immediately explains why van Dijk's machining company in Hoogezand is called Wotan. Although another factor was that he has a predilection for Norse mythology, in which the great and powerful supreme god Wodan sacrifices an eye for wisdom.

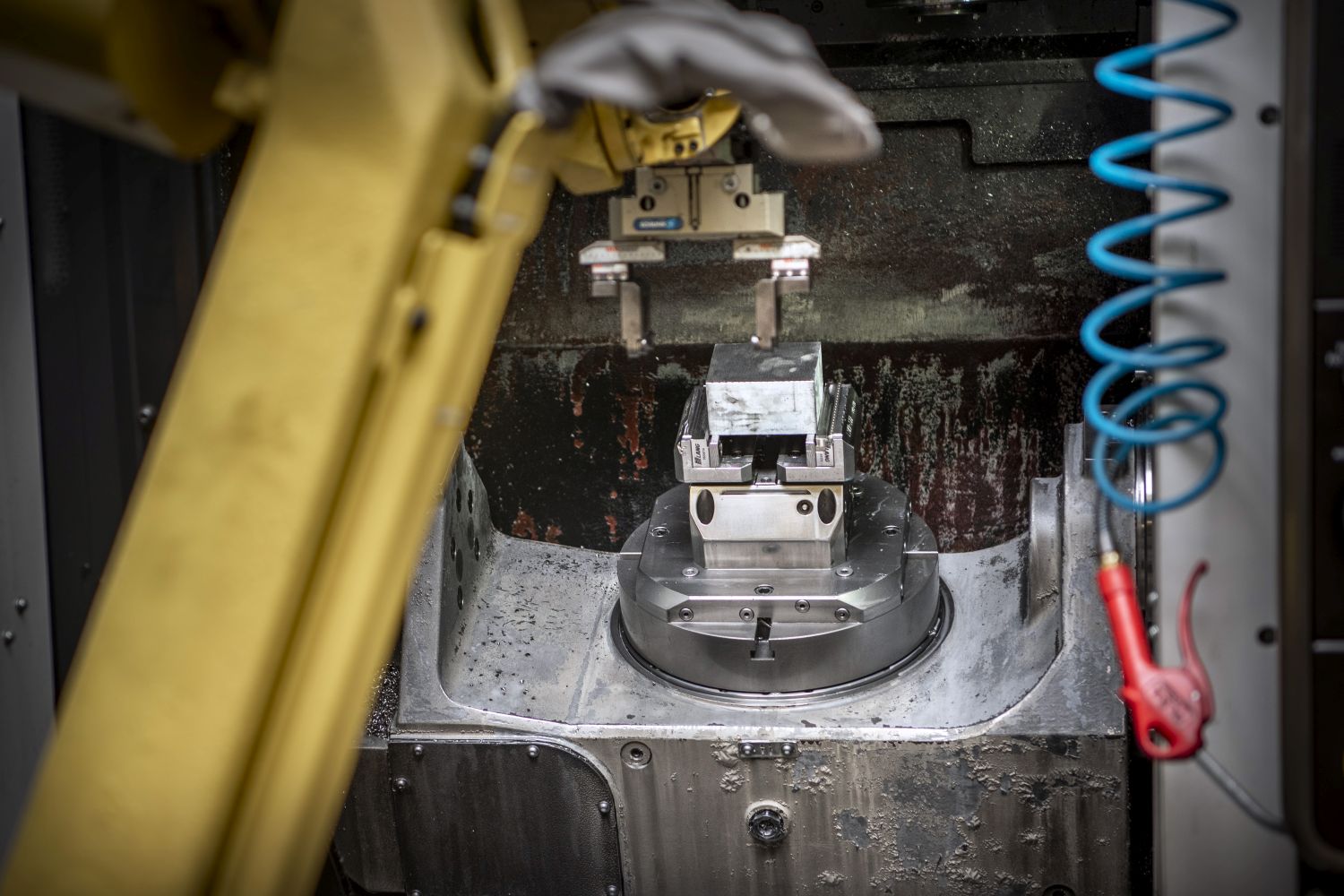

Micron precision work at Wotan

Ken Dijk gives a tour at Wotan. CNC (computer-controlled) machines everywhere, and in one corner of the hall is a honing machine, which is good for micron-precision work (1 micron is one thousandth of a millimeter). With it, holes in a hydraulic steering slide are reworked so that no aerosol of an oil drop can be squeezed through the seam between the sliding parts under high pressure. The techie in Ken Dijk visibly enjoys this.

Wotan is all about machining. This is the same principle as chiseling and milling with wood; the desired shape is obtained by removing material. Dijk began as a one-person operation, but now there are five of them. Some of them are former employees of Amca. And he has a partnership with Rudi Vennik of Zuur Metaalbewerking.

Everything has a link to Amca

Amca is kind of the common thread in Wotan's startup. Machines, employees, contacts, orders - it all has a link to Amca. For example, some products are still being made for Fluitronics in Krefeld, the sister company of Amca that the Chinese have continued with. There are orders for HPV, where former employees of Amca also work. So Amca lives on a bit after all, albeit in Hoogezand instead of Ten Post. Wotan focuses mainly on the production of small series. 'We have to be able to switch gears, because our strength is flexibility and speed. That doesn't work with large series,' says Ken Dijk. Bringing in work is not a problem, he says: 'I have actually had my own company since 2014. Both Vennik and I are never short of work.'

We have to be able to shift gears, because our strength is flexibility and speed. With large series, that doesn't work.

Ken Dijk, Wotan

'Amca closure a once-in-a-lifetime opportunity'

Ken Dijk looks back at last year, when Amca indicated it was closing the Ten Post location. 'I immediately saw it as a once-in-a-lifetime opportunity; I grabbed it with both hands,' he says. He got to work on a business and funding plan and applied to Rabobank for money. Later the GROEIfonds of EBG (Economic Board Groningen, which manages the fund together with NOM) joined him. Says Dijk, "I had heard of the fund, but for a company like mine it seemed a bit far away. Nothing turned out to be less true. He was helped with money. 'They are strict,' Dijk knows, 'but that keeps us on our toes. I had to make a business plan myself. That wasn't a problem because I studied technical business administration.'

Production from China moves toward Europe

Ken Dijk expects great years ahead. He takes into account that more and more production from China is heading back to Europe. 'Those things that come from China are really good quality, make no mistake,' he states. 'But quality costs money. In addition, you have to wait and see if your stuff is always on time and you also have hassles with corona, the Suez Canal and available containers. China is getting more expensive and so is transport. That's going to give effects.'

Veronique Jeunhomme, investment manager GROEI Fund

'We got involved with Wotan through Rabobank. Ken Dijk wanted to continue as an entrepreneur after Amca ceased to exist. He took over machines and started working. Very tough, with a good plan in his back pocket, he just started and it worked. Ken Dijk has a positive attitude, has gathered good people around him, and when he needs advice he turns to this network. Ken is a go-getter and gives you the feeling that things will work out.

Answer 4 simple questions to quickly find out if you may qualify for funding through NOM.