Anyone who wants to stay in the game must catch on and cash in on digital opportunities. With that in mind, Solidd Steel Structures is working hard to transform into a future-proof smart factory. 'Where we are headed is that a bridge is going to tell us when maintenance is needed.'

'There is no escape anymore,' says Jan Willem Stob. 'We can keep doing what we always did, but that's not going to work anymore.' The director of Solidd Steel Structures is referring to the great digitalization battle that awaits the manufacturing industry. Or rather, that fourth industrial revolution, also known as Smart Industry, is already in full swing. 'So you have to seek connections with other parties and think about digitizing your business processes,' he continues. 'And that's exactly what we are doing now, with the support of the Smart Industry Hub North, in full swing.'

Movable steel structures

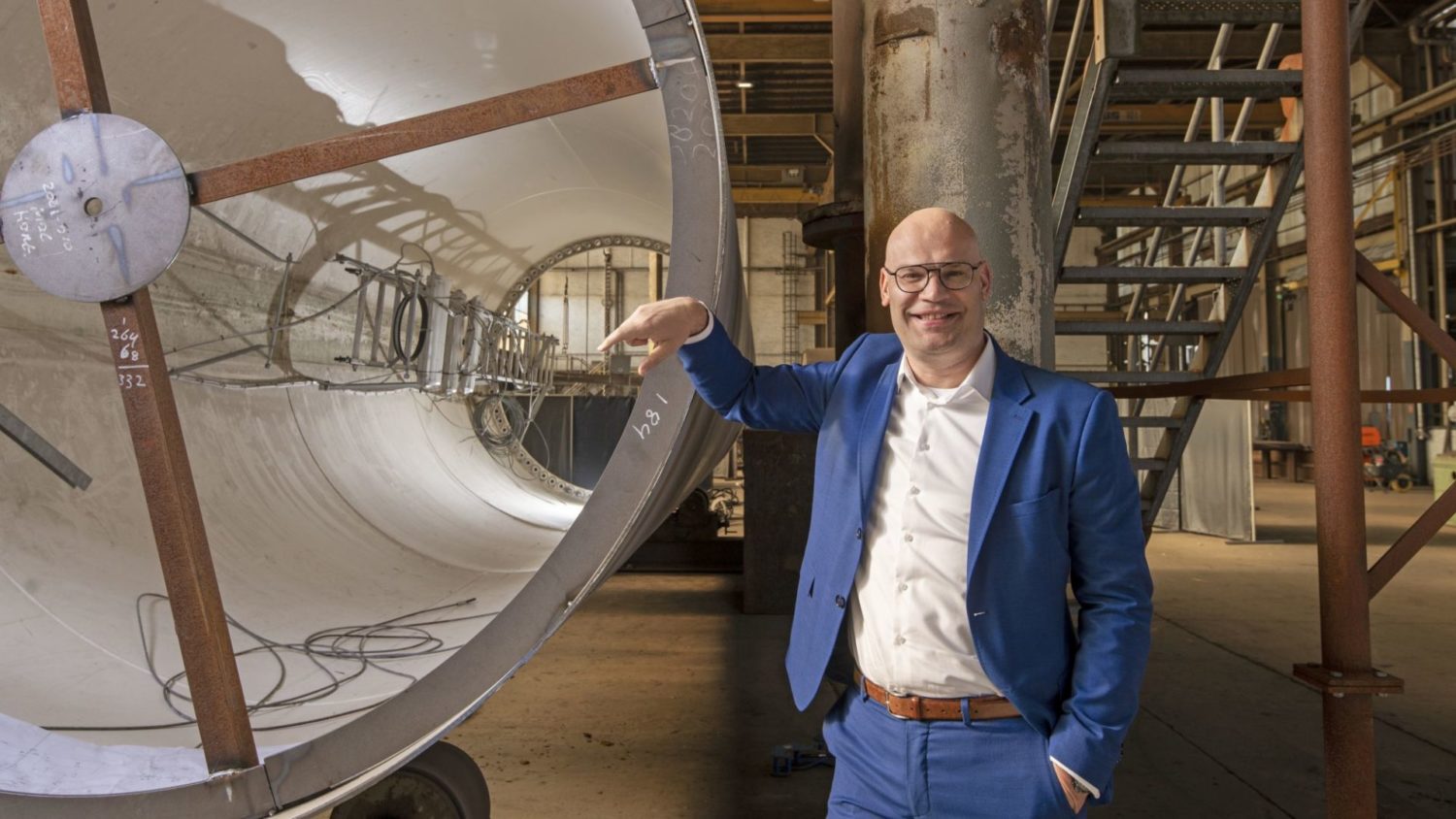

Solidd Steel Structures builds heavy steel structures for bridges, dams, locks, cranes and offshore applications. So an expert in heavy steel construction, and especially in the field of dynamically loaded, movable steel structures. The Friesian company's responsibilities include the construction of the table bridges at Aduard and Zuidhorn and the renovation of the three dam complexes (Driel, Amerongen and Hagestein) in the Lower Rhine-Lek. High-profile projects in which, as with virtually all assignments, the company was responsible for the entire execution process: from design, fabrication and assembly to the actual delivery of the steel product.

Intended successor

Solidd Steel Structures was founded in the fall of 2017, following a relaunch of the bankrupt BSB Staalbouw. Jan Willem, who comes from a civil engineering background, had shortly before been recruited by BSB Staalbouw as the intended successor to the then DGA. 'I told him: I would like to become your successor, but let's take a year or two to do that. In the meantime, we can then look for investors to ensure the succession. Initially, I will then start as Director of Projects & Commerce. That was in July 2017. A few months later, BSB Staalbouw went bankrupt. Together with the management team, Jan Willem decided to look for an investor to buy the company himself. Thanks to the Brabant-based investment fund Neope Capital Management, they eventually succeeded.

Project Organization

'The products that leave the factory here are of incredibly good quality,' Jan Willem emphasizes. 'That is precisely why it is fantastic that the knowledge and craftsmanship of the employees at the time have not been lost. Actually, only the name and the director have changed. In other words, Solidd Steel Structures is a young company with 60 years of experience. However, we have broadened our scope in recent years, for example by positioning ourselves even more emphatically as a builder of offshore structures. This increases our opportunities, because it makes us less dependent on the tender market. Moreover, we are more than just a manufacturing company. At its core, Solid Steel Structures is a real project organization that wants to think along with the client to arrive at the best possible solution. In short, we try to find out the question behind the question.'

Sensor Technology

One of the company's current focal points is exploring the possibilities of digitization, data technology and 3D printing. In particular, data-driven asset management is going to be hugely important for Solidd Steel Structures, Jan Willem knows. 'It's actually crazy that we still maintain bridges because we think we have to do it a few times a year,' he says. 'Where we are going is that a bridge is going to tell us when maintenance is needed. Using sensor technology, for example, we can very accurately map the relationship between actual use and wear and tear. The data obtained then allows us to anticipate this in a targeted way. Or more specifically: sensors indicate, before there is any visible damage, whether or not a bridge needs maintenance. But we can also design and build steel structures much smarter with the right data. Perhaps even with half the materials needed now. After all, thanks to sensor technology, we will soon know exactly where the various forces are located and how wear occurs over time.'

Assessment

Obviously, such a digital transformation process does not happen overnight. It requires time, investment and internal support. But it also requires detailed insight into the current and desired situation. To grow into a smart factory, the Smart Industry Hub Noord offers the company support in this process. The Smart Industry Hub Noord is a platform, with the NOM as the leader and coordinator, that wants companies in the regional manufacturing and process industry to benefit from digital opportunities. Solidd Steel Structures, for example, recently went through an extensive assessment as part of the Smart Industry program.

The assessment is conducted by various partners working together in the Smart Industry Hub, in the case of Solidd Steel Structures by Marije Bakker of FME. The assessment is a scan that allows companies to determine where they stand in terms of digitalization and what steps they can take to become a 'smart factory'. 'Numerous questions on various themes had to be answered,' Jan Willem explains. 'Quite intensive, but incredibly fun to do. As with almost everything here, we involved as many employees as possible. So not an assessment of the management, but of the entire company. Just the conversations we had among ourselves about our further digitalization were very valuable. In that respect, the Smart Industry Hub Noord really held up a mirror to us.'

Data-driven work

But what did the assessment specifically tell Solidd Steel Structures? For example, what should the company focus on in the coming period? 'A number of aspects emerged from the assessment,' argues Jan Willem. 'First of all, we are going to fully commit to working digitally. By that I mean the flow of information that comes in from commerce to production. Now these are still hard transfers. Often in writing, with drawings and a story. We are going to digitize that entire process from beginning to end.

In addition, data-driven work is also getting a prominent role in our operations. This means that we will make optimal use of all the data that we collect, process and store everywhere and nowhere. Based on all those numbers, we will steer the company wherever possible. Obviously, we also have to think about implementing robots in our organization. Robotization is an irreversible development in our field. However, it does not mean that you will replace people. It does mean that you can use them more efficiently.'

Collaborate

A number of employees are currently attending a master class in Digital Leadership, also part of the Smart Industry program. So how do I deal with digital changes? At the same time, Solidd Steel Structures, together with electronics company Interay Solutions from Burgum, is investigating how sensor technology can be applied in the best possible way in bridge maintenance. 'On the road to further digitalization, the connection with other companies is invaluable,' Jan Willem underlines. 'Very different from say 10 years ago when everyone often kept their cards in front of their chest. If you want to move forward in Smart Industry, you just have to work together.'