Jan Geerts is founder of Getech from Westerbork and initiator of Binder 3D, a living lab to discover opportunities within industrial 3D printing, which recently obtained formal Fieldlab status. Two separate entities: one is a forerunner in Smart Industry, the other helps companies take that role as well. "Every machine builder should understand 3D printing.

He knew Jan Geerts wanted to start his own business when he graduated from the MTS. Coming from an entrepreneurial family, he was brought up with ideas and new opportunities everywhere. Nevertheless, he started his career "simply" as an employee in various machine factories, including as a foreman, draughtsman, structural engineer and manager. 'Everywhere I worked, I thought: I can do that myself and maybe even better,' Jan says. 'I had the same thought when I heard that a client, a company that made air conditioning pipes for Mitsubishi in Almere, needed measuring jigs. I immediately felt that there were opportunities there and that I had to do something with them. And so in 2003 I decided to start my own business and make measuring jigs for the automotive industry under the name Getech.

Steady and healthy

A measuring jig is an arrangement in which it is possible to test with extreme precision whether a pipe fits in the scarce space in front of and under a car and connects properly everywhere. Think of pipes for fuel, A/C fluid and brake fluid, for example. And yes, to ensure a smooth and flawless car production process, those pipes must of course have the correct lengths, curves and attachment points.

His feelings by no means let Jan down, quite the contrary. Building measuring jigs, also called control jigs, turned out to be a gap in the market. 'Since its founding, Getech has grown very steadily and healthily,' he says. 'Especially after we gained a foothold in the German auto industry, things moved quickly. Since then we have gone all over the world from Westerbork. Indeed, in the field of measuring jigs for pipe systems in cars, we have now become the most important player in the global market.'

Looking Ahead

But what exactly is Getech's strength? A clear answer to that question was once given, at a trade fair, by a German customer. You offer a "Rundum-Sorglos-Paket," he explained the success of the company from Drenthe. 'By this he meant: we place a 3D drawing or 3D model with you and then get 100% good measuring jigs in return,' Jan clarified. 'So the customer doesn't have to worry about anything. We really go a long way in unburdening customers. We always try to look five years ahead. What drives a company, where does it want to go and how can we act on that and lead the way? We don't just have someone walking around here who does nothing but take care of process optimization. That costs a lot of money, but delivers a lot more. Simply because you not only have to look at what is being asked, but especially at how you can do it better.'

Smarter growth

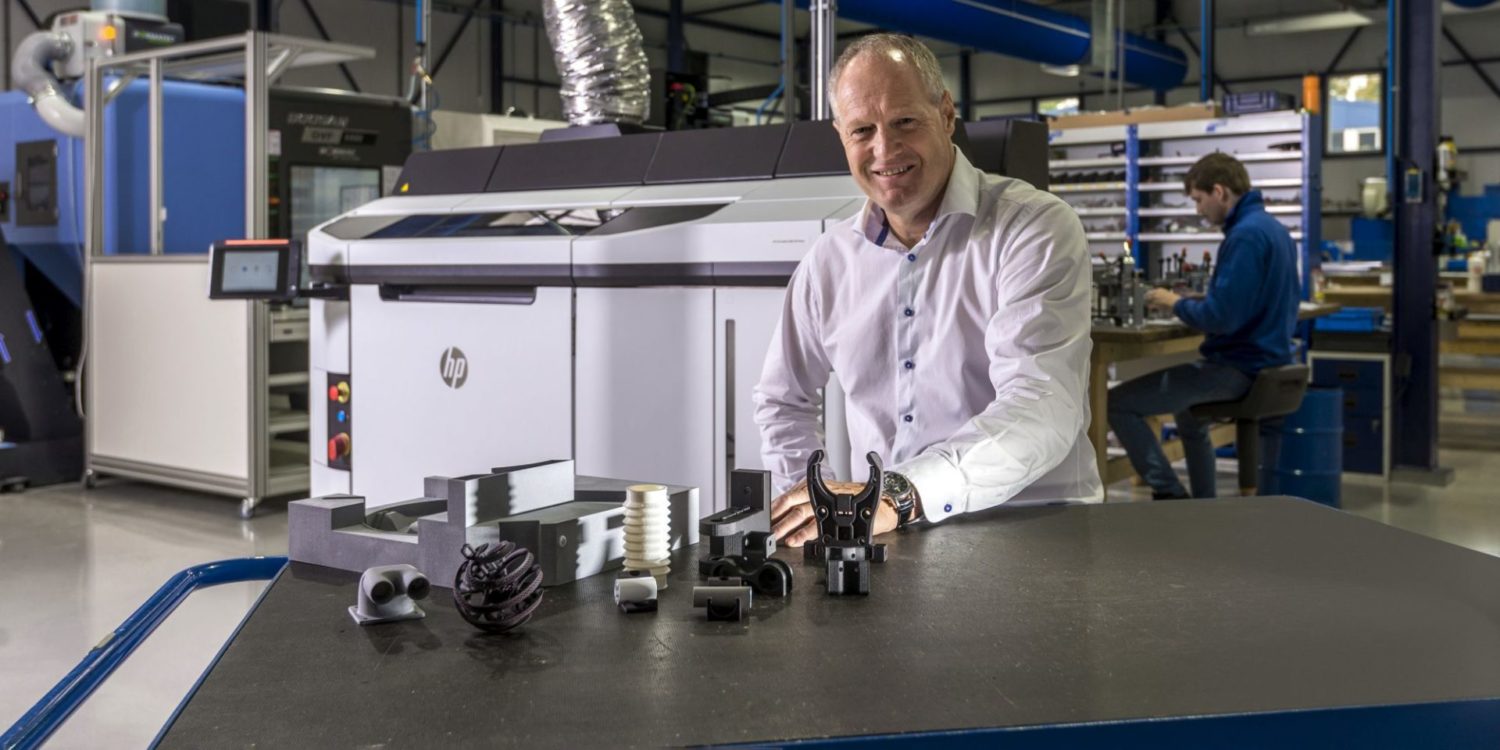

To work even smarter and more future-proof, Jan closely follows all developments in Smart Industry in particular. For example, a few years ago he stumbled upon a study by the international accounting and tax consulting firm PwC that concluded that industrial 3D printing will change everything in the manufacturing industry in the near future. In other words, a substantial portion of what is produced by Getech and other manufacturing companies will be printed. And if 3D printing is seen as, as PwC described it, the key to smarter growth, Jan obviously wanted to be there as early as possible. 'I then purchased about three 3D printers and put them with my engineers. But I soon discovered that they had little or no knowledge of them. In itself not that surprising, because making a design for a 3D printer requires a completely different mindset than designing for, say, a milling machine. Still, how to proceed? That's when the idea for Binder 3D was born in 2019, a physical experimentation environment for Northern Netherlands SMEs to discover and exploit opportunities in 3D printing together. After all, I believe that every mechanical engineer should understand 3D printing.'

Learning network

A grant application was successfully submitted. Among others, Samenwerkingsverband Noord-Nederland (SNN) and the Province of Drenthe contributed to make the living lab a reality. At the same time, the initiative is also supported by both suppliers from the 3D printing industry and knowledge institutions such as NHL Stenden, University of Groningen, Drenthe College and Alfa-college. Last year, this resulted in the official launch of Binder 3D. The goal is to put the Northern Netherlands on the map as the 3D printing region of the Netherlands. Too ambitious? Certainly not, thinks Jan. "For years I looked around everywhere and always came across Brainport Region Eindhoven. There you see numerous initiatives and cooperation clusters that successfully focus on 3D printing. Although we are currently lagging behind in terms of knowledge development, we can do the same here. In my opinion, we are far too modest in the north, while there is a lot of potential. Just down-to-earth thinking can take us very far. That is why I took the initiative with Binder 3D to work with companies and knowledge institutions to raise the level of knowledge in the region to a higher level. Among other things by establishing collaborations and creating a learning network'.

Right choices

Although located in the same building in Westerbork, Getech and Binder 3D are two separate entities. The beauty of such shared accommodation is that companies can get a good understanding of the benefits that Getech derives from 3D printing. And precisely ensuring a better understanding is important to remove barriers. 'In the living lab, companies are put together in groups to gain experience together and try out the possibilities for themselves,' Jan explains. 'They may submit a case themselves or, if desired, we can do so. By thinking about it and working on it you make each other stronger. For example, how do you make the right choices? And do you have to want all those printers yourself? At Binder 3D we have ten different printers, all with different properties. So you can as a company test which printer does or does not suit you.

Formal status

Already, Binder 3D is being widely embraced. Not for nothing did the living lab recently obtain the formal status of Smart Industry Fieldlab. "The NOM has supported us very well in this," emphasizes Jan. 'Of course, such an official status does not change anything about our idea, but it does give you more prestige to the outside world. Whether Binder 3D meets expectations so far? Yes, we are very well on our way. We have a board in the experimental garden that lists all the organizations that are partners or members. Currently, the counter stands at 25. The goal is to reach 60 affiliated parties within three years who will learn together and together take the lead in the Netherlands. I am firmly convinced that it will succeed.