After projects in the infrastructure and construction sectors, KNN Cellulose - a pioneer in the circular economy - is now also taking concrete steps in the chemical industry. In the multi-year project Cell-U-Value, cellulose extracted from waste is being reprocessed into usable chemical raw materials.

Reusing waste paper is the best known form of cellulose recycling. KNN Cellulose - part of the NOM portfolio since 2017 - goes one step further. "We focus on tertiary cellulose from waste streams, such as milk packaging and pizza boxes," explains director Erik Pijlman. "Waste that now ends up in incinerators, while the cellulose present is perfectly reusable. The same goes for the tons of toilet paper we flush away every year. Technologically it is possible to recover cellulose from waste and reprocess it into raw materials for the construction and infrastructure sector. For example, several bicycle paths have already been built with our product Recell."

Less CO2 emissions

Pijlman knows that the chemical industry is also searching in abundance for sustainable raw materials. "That's why in the Cell-U-Value project we focus specifically on the chemical industry. We have already discovered that it is possible to convert cellulose into acetic acid, which is processed in the semi-finished product MCA (mono-chloro acetic acid, ed.), for example. "

If we can apply this conversion on a large scale, we will make a double profit: by reusing waste that would otherwise be incinerated, we reduce CO2 emissions and the industry needs fewer fossil raw materials. In converting cellulose, we are using a sustainable technology."

Harnessing potential

The Cell-U-Value project was initiated in a collaboration between KNN Cellulose, University of Groningen, Nouryon (formerly AkzoNobel Specialty Chemicals) in Delfzijl and the national cluster organization Institute for Sustainable Process Technology (ISPT). "The fact that these parties have joined confirms the value we see in cellulose," says Pijlman, who is taking the lead in Cell-U-Value as project leader. "New connections are emerging in the chain with a circular focus. We are happy about that, because that is essential to really exploit the potential of cellulose as a sustainable raw material."

Scaling up in the region

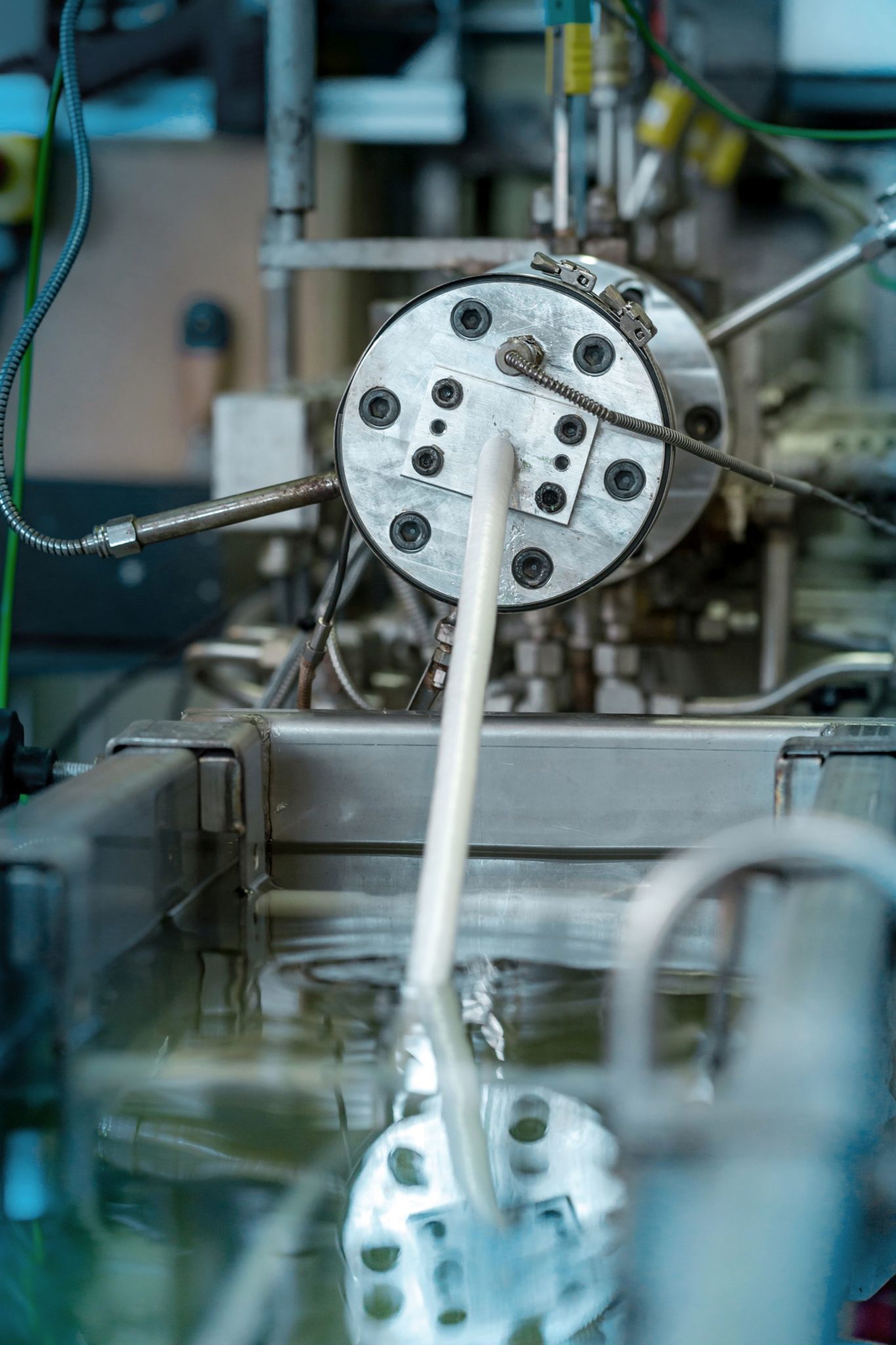

As a pioneering entrepreneur, Pijlman enthuses that everything is available in the northern Netherlands to make Cell-U-Value a success. "We have the Chemport network here and there are excellent innovation centers available. For example, we are starting with a lab-scale feasibility study at the ZAP facility Groningen and at a later stage we can continue to develop at the new Chemport Industry Campus. Conversion is the basis: we convert cellulose by hydrolysis and fermentation, integrated with reactive extraction. First we will optimize this technology, then scale up to larger volumes. Ultimately, we want to be able to produce at least 10 tons of bio-based chemicals from cellulose in a processing pilot."

Complete value chain

The multi-year project runs until October 2022. "Innovative steps like this take a long time," knows Pijlman, who started KNN Cellulose in 2015. "It's worth it, because with Cell-U-Value we are giving a boost to the circular economy. Our approach is to create a complete value chain that pays off both economically and ecologically. The technology is a hard requirement, but more is needed than large installations and complex processes. It requires vision and insight to turn waste into new products and new forms of collaboration within the chain to create a market. This movement is accelerating as the urgency of the climate issue increases. In that sense, we are running with the times."

KNN Cellulose cordially invites potential suppliers to participate in the project, for example from the recycling and paper industry, waste treatment and sewage treatment.